Milling Attachment |

|

||

Cost |

$400 |

|

Instructions |

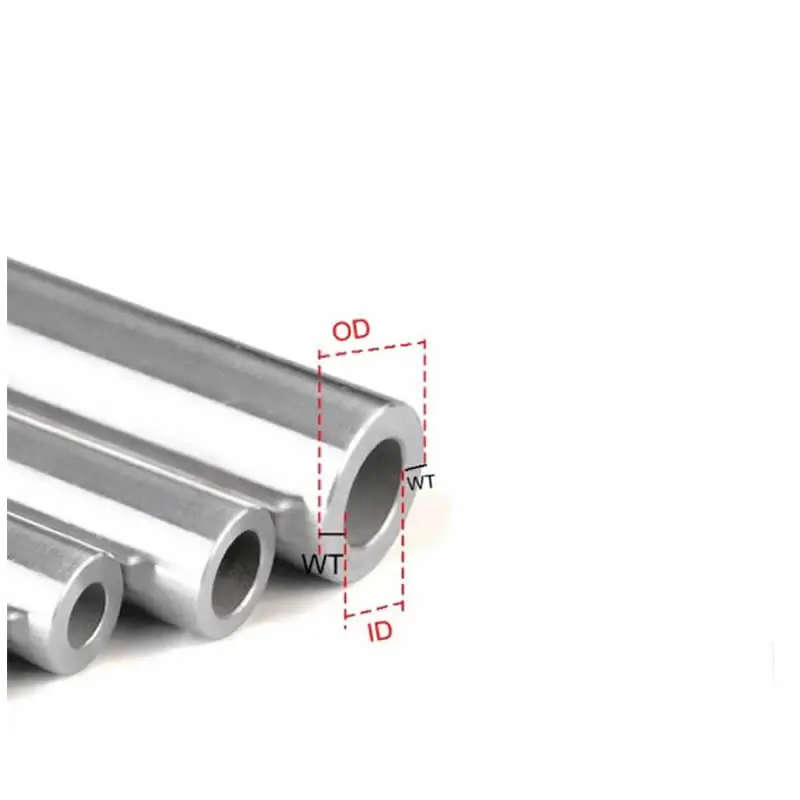

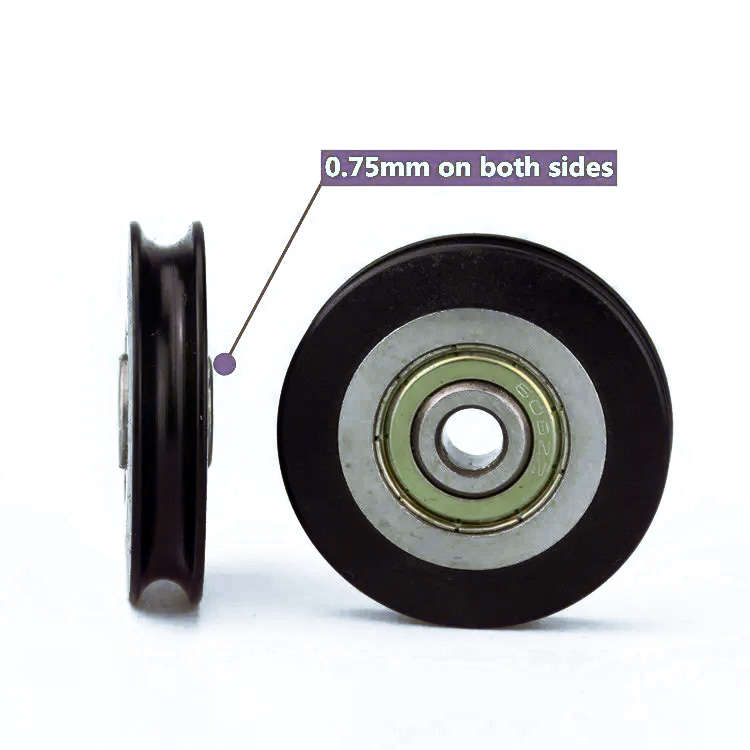

The milling attachment of this project (linked below) is made in China and is marketed under the trade name Sincere. It's sold as an accessory to the Chinese made Sincere C6104 watchmaker's lathe but can be used with any cross slide that it can be mounted on. It's also sold by Boley in Germany as a lower cost alternative to their Leinen milling attachment under the trade name Vector. At under $400 it is significantly less expensive than milling attachments made by Schaublin, Leinen and Levin, which all cost in the $5,000 range, but is nevertheless of good quality. I use it on both my B8 and W12 lathes. As the milling attachment requires belt power, this project includes instructions and links to make your own belt and pulley system to power this or any other 3mm or 4mm round polyurethane belt driven milling attachment. It uses pulley wheels with sealed bearings designed for a 6mm shaft connected with aluminum cross blocks to 12mm steel tube. 12mm-12mm cross blocks are used to connect the tubes. 12mm-6mm cross blocks are used to connect the wheels using M6 bolts to secure the wheels to the cross blocks. If you already have a variable speed motor you can use it to power the belt and pulley system directly or by adding a countershaft. For my W12 lathe I power the belt and pulley system with an additional wheel that I added to the countershaft that came with that lathe. For my Boley lathe I power the belt and pulley system directly with the variable speed motor that powers that lathe. The instructions and links for the inexpensive but powefull variable speed and reversible 5000 rpm DC motor that I use to power my Boley lathe and milling attachment are on the Lathe Motor project page. Note that in most cases the lathe spindle will need to be disengaged from belt power when the milling attachment is engaged. With stretchy 3mm or 4mm round polyurethane belts this generally does not pose a problem as it's easy to pull the belt off of both wheels. However, with flat belts that don't stretch as much you may need to mount your motor or cross slide so that it can slide enough to disengage fully from the lathe's drive belt when the milling attachment is being used as I have done on my larger W12 lathe. Steps: (1) Consider which orientation best suits the work and attach the milling attachment to your cross slide accordingly. The milling attachment's spindle can be rotated to any angle and oriented in either direction. (2) Sketch the designs that work for your lathe and use a hacksaw to cut the 12mm steel tube to the corresponding lengths. (3) Connect the 12mm steel tubes using the 12mm-12mm aluminum cross blocks. The system will need to be configured differently for each position of the milling attachment. I recommend buying enough 12mm steel tube, cross blocks and pulley wheels to be able to experiment with different configurations. (4) Connect the pulley wheels using M6 bolts with nylon locknuts so they don't loosen and fall off.

(5) Cut the polyurethane (PU) belt to length using scissors and then join the two ends. To join the ends heat the tip of a box cutter blade with an alcohol lamp or a small hardware store torch. Touch both ends of the belt to the red hot blade to melt the ends then quickly join the ends so that they fuse together. After cooling test for strength and then clip off any excess melted material using fingernail clippers.

(6) Experiment with different configurations and belt tensions by sliding and rotating the cross blocks on the tubes. Adjustable clamping lever handles can be used to replace the bolts in frequently adjusted cross blocks to make adjustments quicker. | |

Parts |

The total parts cost for this project (not including shipping) is under US $400! These links frequently break as vendor inventory changes. Please contact me if you encounter a broken link. Where multiple quantities and or variants are offered please take care to select the quantity and variant that matches my description. You can of course vary the quantity, but because it can be difficult to know exactly how your pulley system is going to be configured before playing around with it I've suggested quantities that already take into account my suggestion of overbuying rather than underbuying. |

|

Milling Attachment https://s.click.aliexpress.com/e/_DmW50hD or https://s.click.aliexpress.com/e/_oCzra1C |

||

12mm steel tube (select 2 pieces, OD 12mm ID 8mm) |

||

12mm x 12mm Cross Blocks (select 3 pieces, 12-12) |

||

12mm x 6mm Cross Blocks (select 2 pieces, 12-6) |

||

Pulley wheels (select 1 set of 5 pieces) |

||

Polyurethane belt (select Diam 4mm, 5 meters) |

||

Adjustable clamping lever handles (select 4 pieces, screw type M4 x 16mm) |

||

Links |

For links to supplies including brass and steel stock, gravers, sharpeners, and gear cutters see the Shop page. |