#!/usr/bin/env python3

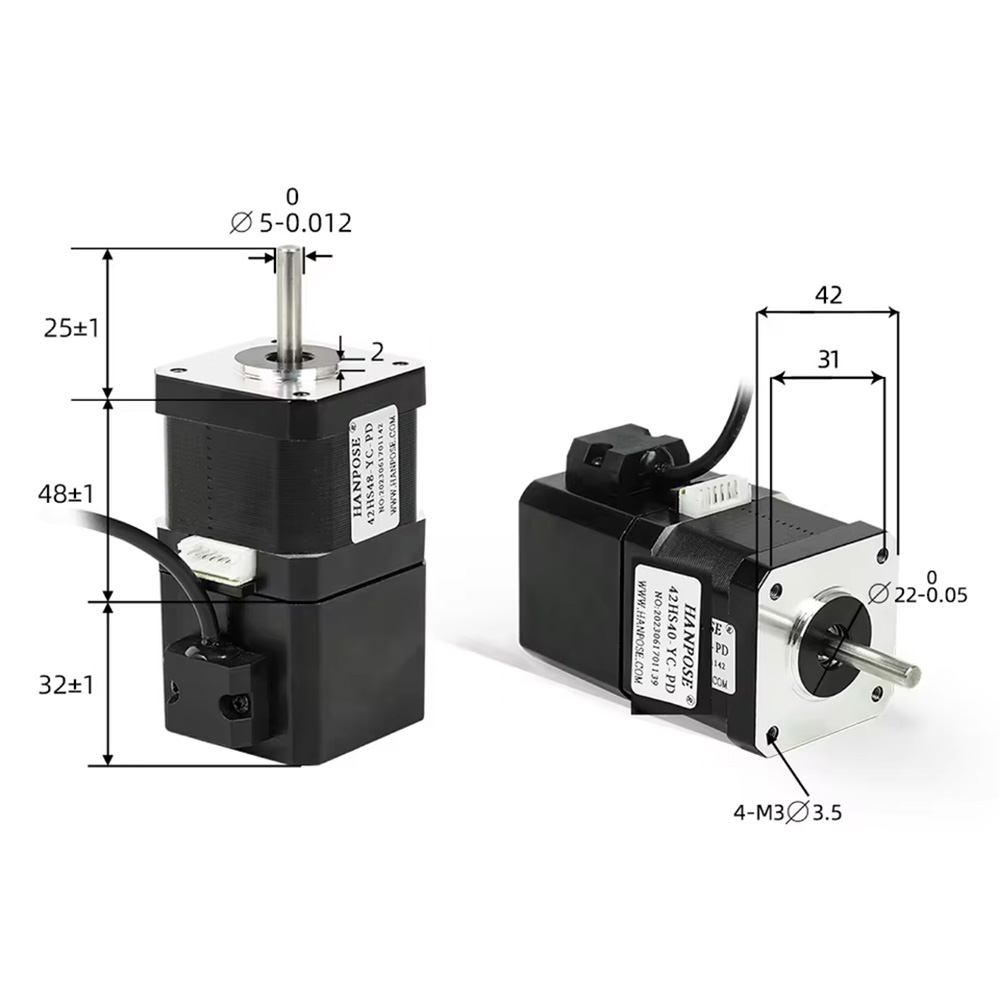

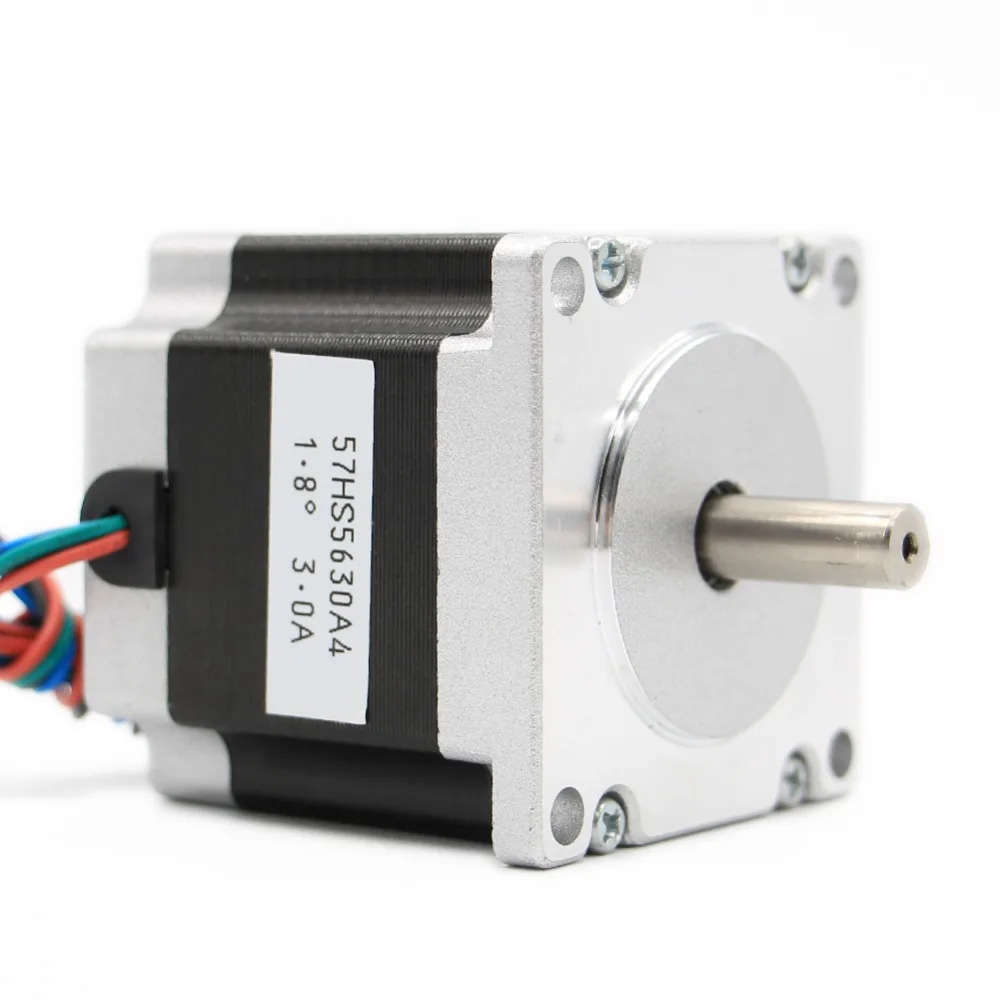

# CNC_Index_Driver_2025.8.28BV3 with 1/32 microstepping and brake

# Copyright ©2024-2025 Dayton Taylor

import os # operating system functions for shutdown when finished

import sys # system functions to support exit option at end of process

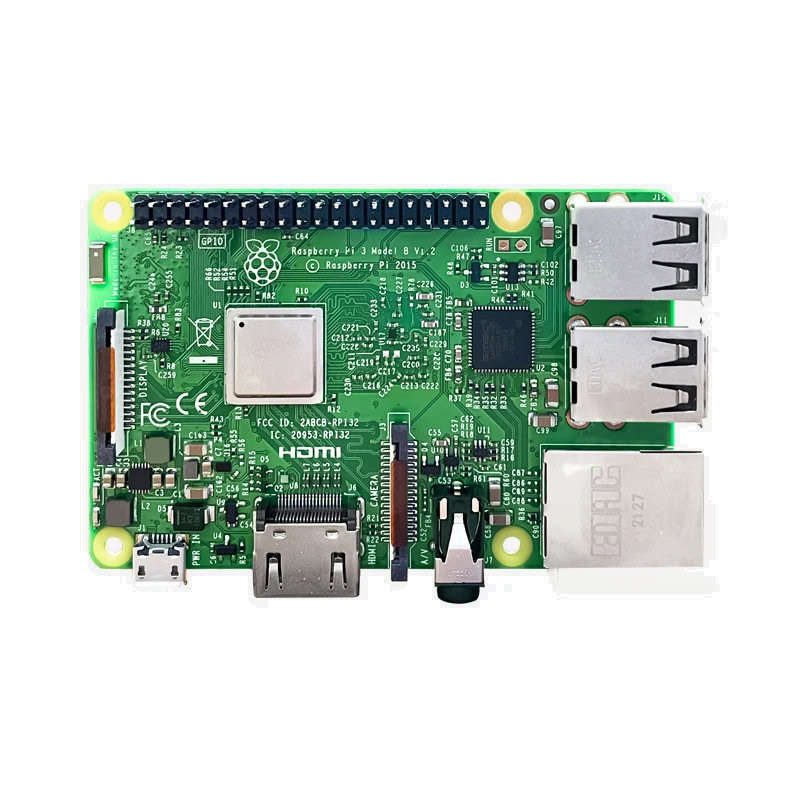

import RPi.GPIO as GPIO # general purpose input output functions for stepper motor GPIO controls

import time # for time delay function

from datetime import datetime # module to get time and date for display (only works with

# an internet connection because stock Rasberry Pi doesn't have realtime clock)

#

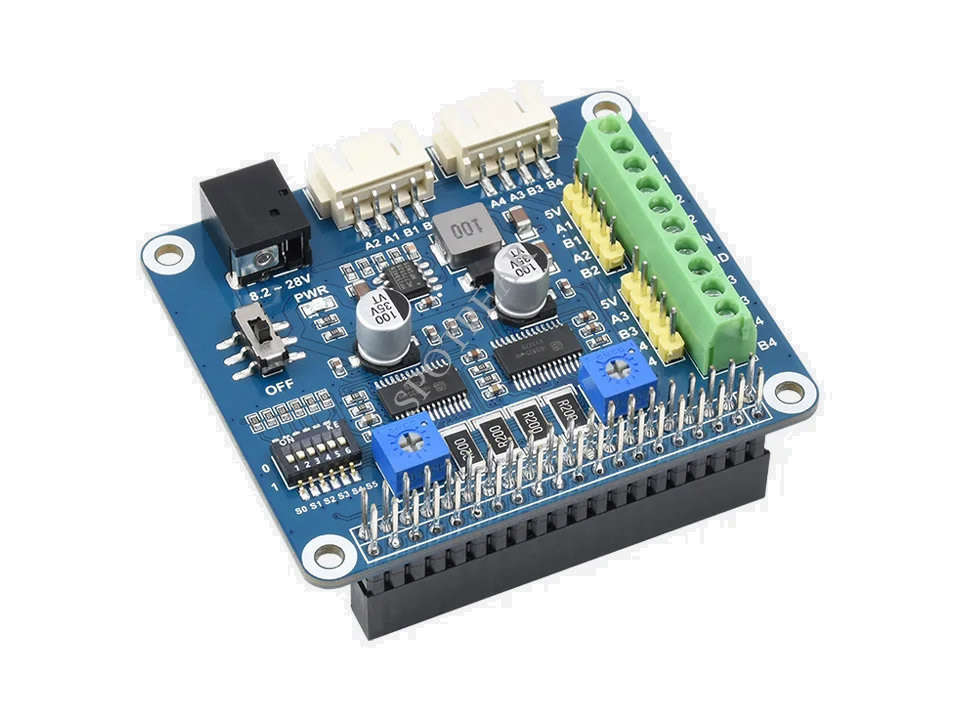

# HR8825 stepper motor chipset driver

from HR8825 import HR8825 # chip-specific function module for Waveshare stepper motor HAT (B)

#

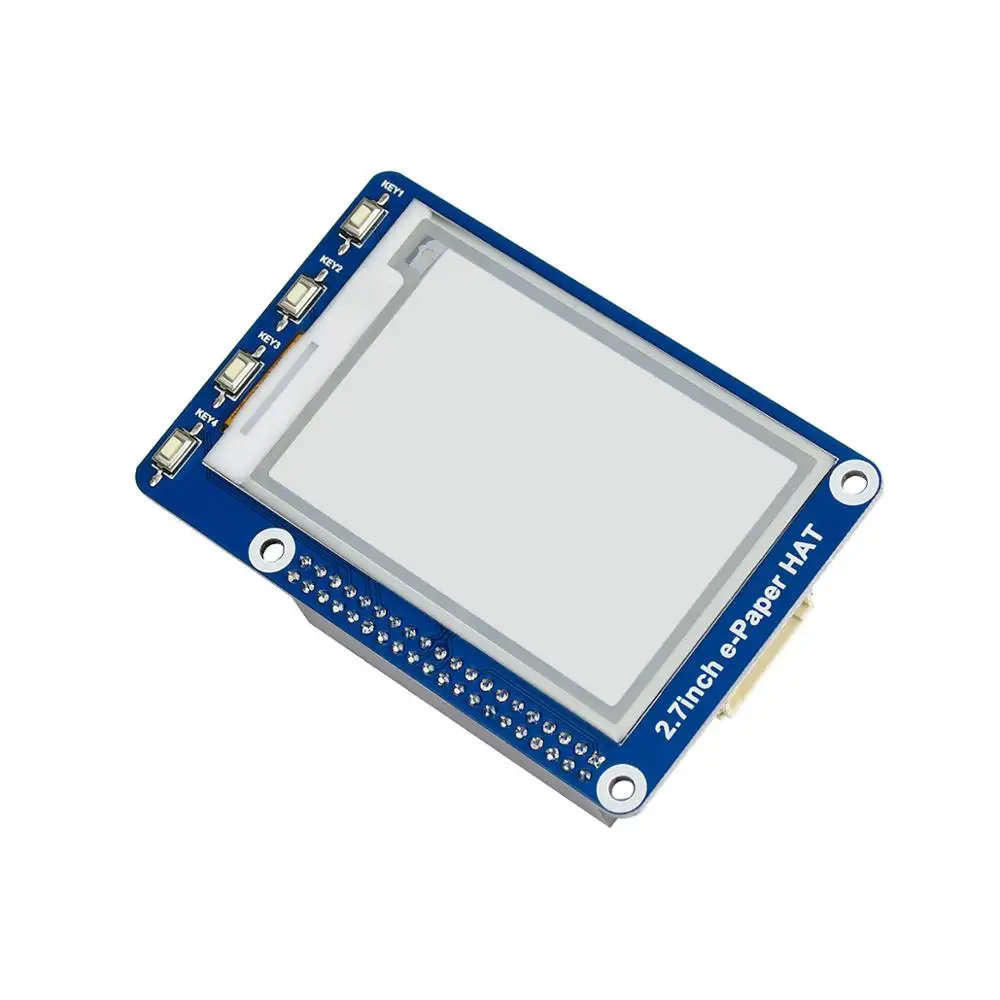

# GPIO functions for button control for e-paper display buttons

from gpiozero import Button # GPIO functions for button control for e-paper display buttons

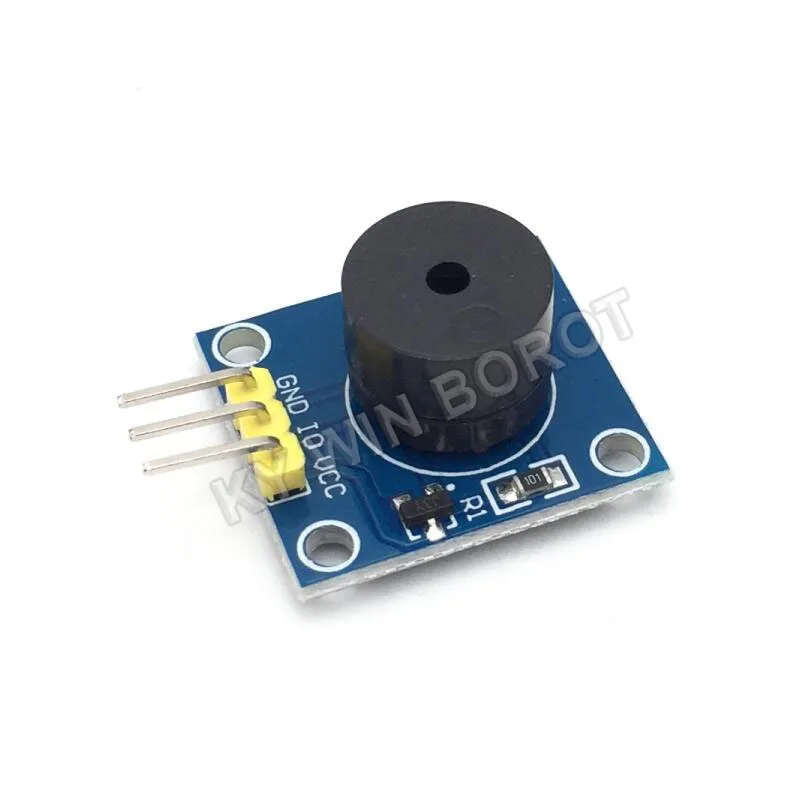

from gpiozero import Buzzer # GPIO function module for audible system ready prompt

from gpiozero import TonalBuzzer # Buzzer module of tonal functions for audible system ready prompt

from gpiozero.tones import Tone # TonalBuzzer module supporting TonalBuzzer tone profiles

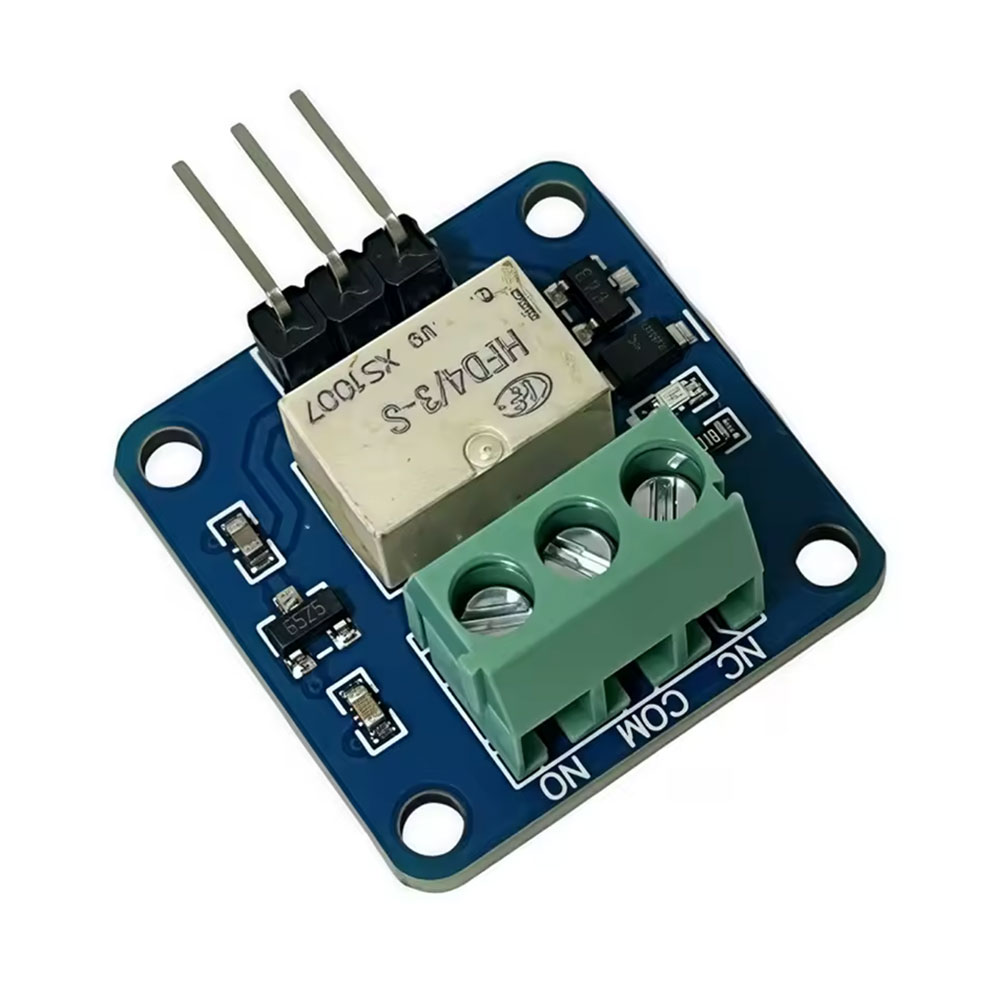

from gpiozero import OutputDevice # GPIO functions for relay control for stepper motor brake

#

#import epd2in7 # function module to support Waveshare e-paper 2.7 inch black & white e-paper display driver

from waveshare_epd import epd2in7_V2

from PIL import Image, ImageDraw, ImageFont # display drawing functions to support drawing on e-paper display

#

from pygame import mixer # game design module to support audible system ready prompt when speakers are available

# the two lines below initiate the pygame .wav player for beep sound (beep prompt only works when external

# sound output device is available and selected in system sound preferences)

mixer.init()

alert=mixer.Sound('/home/pi/CNCIndexDriver/python/wave1.wav')

#b initiate TonalBuzzer module in gpiozero

b = TonalBuzzer(2) # set TonalBuzzer signal output pin to GPIO pin 2

#brake - initiate brake output in gpiozero

brakerelease = OutputDevice(3) # set brake signal output pin to GPIO pin 3

# assign gpiozero support for e-paper display buttons to physical GPIO pins on Waveshare e-paper display

buttonA = Button(5)

buttonB = Button(6)

buttonC = Button(13)

buttonD = Button(19)

epd = epd2in7_V2.EPD() # use the epd2in7_V2 module to name the e-paper display 'epd'

epd.init() # initialize the display by referencing its name and the 'init' function

print("") # print a carriage retutn (blank line) to console (command line terminal window)

print("Clear e-paper display") # print text to indicate that the e-paper display is being cleared

print("") # print another blank line

epd.Clear() # clear the display by referencing its name and the 'clear' function

def printToDisplay(string): # define what happens when e-paper printToDisplay function is called

epdImage = Image.new('1', (epd2in7_V2.EPD_HEIGHT, epd2in7_V2.EPD_WIDTH), 255)

draw = ImageDraw.Draw(epdImage) # create draw object and pass the image layer epdImage

# set the font paths, file names, and sizes (Font.ttc is the GilSans TrueType font)

font = ImageFont.truetype('/home/pi/CNCIndexDriver/Font.ttc', 18)

fontsmall = ImageFont.truetype('/home/pi/CNCIndexDriver/Font.ttc', 12)

fontsupersmall = ImageFont.truetype('/home/pi/CNCIndexDriver/Font.ttc', 9)

draw.line((36, 23, 264, 23), fill=0) # draw top line

#

# The line below is the text on the display that changes step-by-step.

# The remaining elements below it are the same on every page.

# draw the page text (page1, page 2, page3 or page4) starting 42 pixels to the right and 2 pixels down

draw.text((42, 2), string, font=font, fill=0)

#

# draw the bottom section of the screen with copyright, date and time.

# assign the name 'now' to the current date and time

now = datetime.now()

# define the layout of the datetime string using the function 'strftime'

dt_string = now.strftime("%Y / %m / %d %H:%M:%S")

# strips the first two characters (20 from 2024) off the date time string

dt2_string = dt_string[2:]

#

draw.line((36, 158, 264, 158), fill=0) # Draw bottom line

# draw the © and Date Time String text at bottom

draw.text((44, 160), f"©2024 Dayton Taylor {dt2_string} ", font=fontsmall, fill=0)

# draw the left section of the screen with button descriptions

draw.text((2, 0), f""" A """, font=font, fill=0) # buttonA Text

draw.text((2, 18), f""" Start """, font=fontsupersmall, fill=0) # buttonA Text

draw.text((2, 28), f""" Process """, font=fontsupersmall, fill=0) # buttonA Text

draw.line((36, 0, 36, 176), fill=0) # vertical line to the right of button descriptions

draw.text((3, 45), f""" B """, font=font, fill=0) # buttonB Text

draw.text((2, 63), f""" Load """, font=fontsupersmall, fill=0) # buttonB Text

draw.text((2, 73), f"""Program """, font=fontsupersmall, fill=0) # buttonB Text

draw.line((0, 44, 36, 44), fill=0) # horizontal line under the buttonA description

draw.text((1, 89), f""" C """, font=font, fill=0) # buttonC Text

draw.text((2, 107), f""" Run """, font=fontsupersmall, fill=0) # buttonC Text

draw.text((2, 117), f"""Program """, font=fontsupersmall, fill=0) # buttonC Text

draw.line((0, 88, 36, 88), fill=0) # horizontal line under the buttonB description

draw.text((2, 133), f""" D """, font=font, fill=0) # buttonD Text

draw.text((2, 151), f""" About """, font=fontsupersmall, fill=0) # buttonD Text

draw.text((2, 161), f""" Exit """, font=fontsupersmall, fill=0) # buttonD Text

draw.line((0, 132, 36, 132), fill=0) # horizontal line under the buttonC description

#this function sends the image that has been created above (epdImage)to the display

epd.display(epd.getbuffer(epdImage))

time.sleep(2)

def handleBtnPress(btn):

# switcher number represents the GPIO button pin number

# value is the message it will print - variables page1 - page4 will be defined below

switcher = {

5: f"{page1}",

6: f"{page2}",

13: f"{page3}",

19: f"{page4}"

}

# get the string based on the passed button and send it to printToDisplay()

msg = switcher.get(btn.pin.number, "Error")

printToDisplay(msg)

# tell the buttons what to do when pressed

buttonA.when_pressed = handleBtnPress

buttonB.when_pressed = handleBtnPress

buttonC.when_pressed = handleBtnPress

buttonD.when_pressed = handleBtnPress

# now that we've initated the functions and defined the screen layout and button behavior

# we can begin the full program 'while True' loop so the process can be repeated multiple times

while True:

# The section below is the initial text for the screens that are called when you press a button.

#

# Note that this text is updated later in the script and can contain variables

# provided that they are initialized and are if the type 'string'

# the reason this text is inside of the first 'while True' loop is so that page3 is reverted back to its

# start condition if the process is restarted, which is one of the options at the end of the script

#

# Note also that page3 is initiated for a special condition where button C is pressed before

# n has been defined - it will be redefined to contain applicable variables

# after those variables are initiated

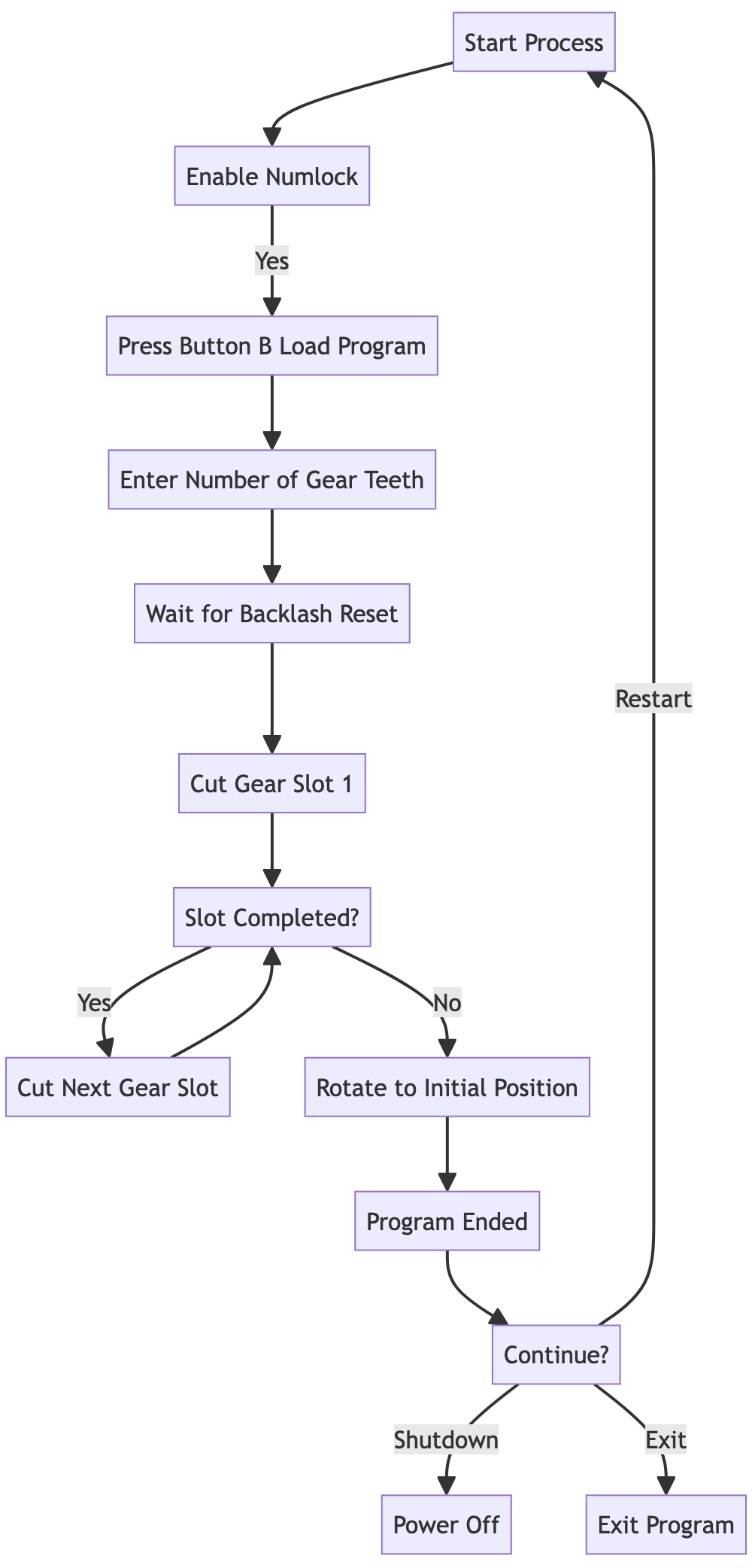

page1 = f"""A) CNC INDEX DRIVER

To start process:

Enable numlock on keypad

Enter 1 to enable buzzer

Enter 0 to disable buzzer

Press button 'B' on this unit

"""

page2 = f"""B) LOAD PROGRAM

Enter number of gear teeth

Wait for backlash reset

Wait for display prompt and

beep before cutting each slot

"""

page3 = f"""C) RUN PROGRAM

You may now cut gear

slot 1

When finished enter 1

(or 999 to return to

zero position)

"""

page4 = f"""D) ABOUT / EXIT

Enter 0 to shut down

Enter 1 to start over

Enter 2 to end the program

12V, 3A, CNC Index Driver

HR8825 200 Steps/360 1.8º

1/32 Microsteps, 6400 Steps

"""

# this next major section of the script initiates the process by asking the user to input the number of gear

# teeth to be cut before dropping into the loop that will repeat for each position

#

# start the user interface - both the command line and the e-paper display begin guiding the user through

# the process

try:

print("Print 'Start Process' instructions to e-paper display")

print("")

printToDisplay(page1) # Print e-paper page1 contents to e-paper display.

#

# set up motor driver GPIO driver (this must be done initially

# and again each time e-paper printToDisplay has been called to toggle between GPIO control

# by the gpiozero module (which controls the display) and the RPi.GPIO module (which controls

# the stepper motor)

#

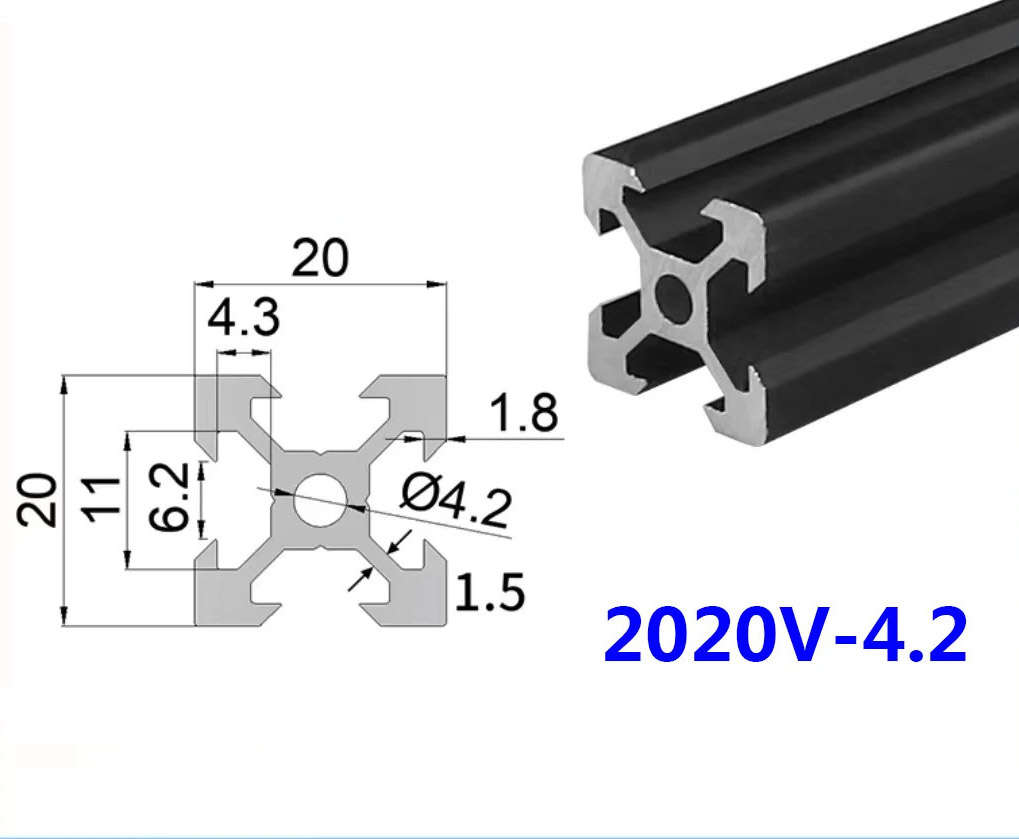

Motor2 = HR8825(dir_pin=24, step_pin=18, enable_pin=4, mode_pins=(21, 22, 27))

#

# this next section is a comment noting microstepping command syntax for the stepper motor

# this script is designed to use microstepping with no gearbox at 1/32step microstep resolution

# this is equivalent to 6400 steps per 360 degrees of rotation

#

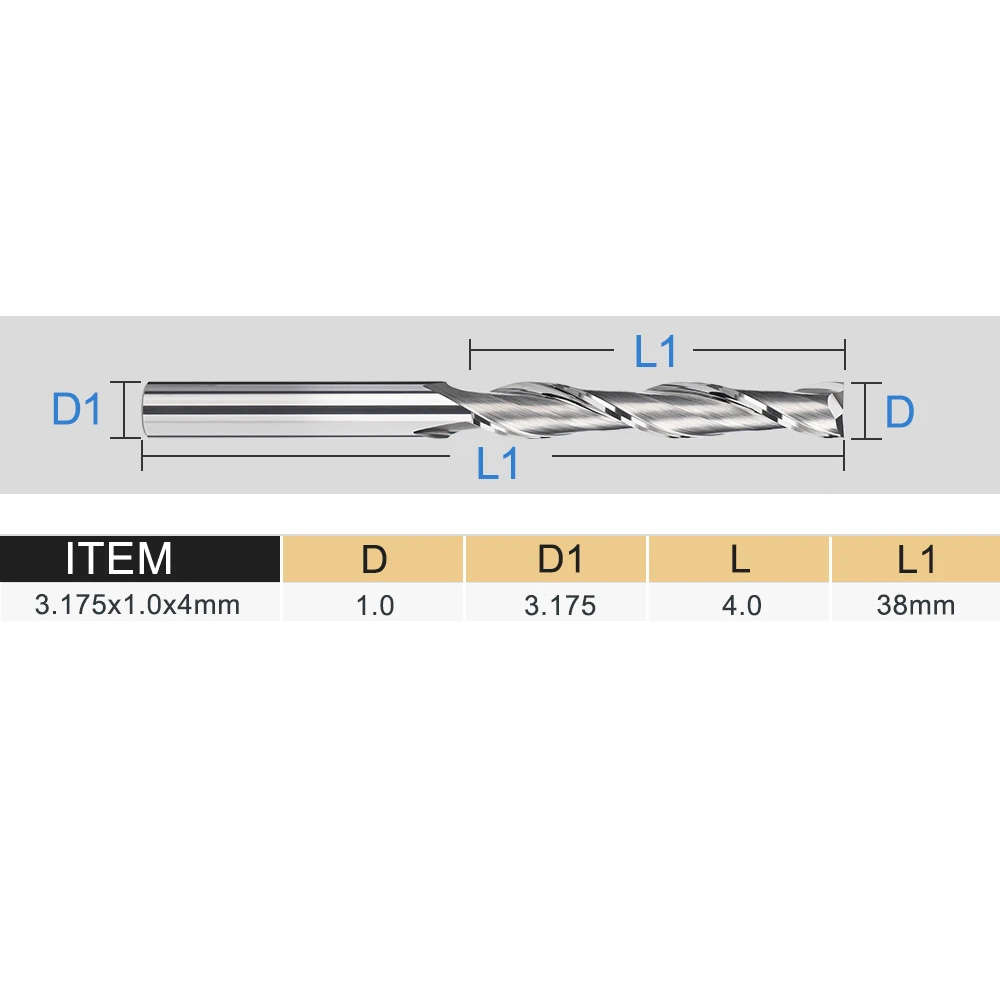

"""

# 1.8 degree: nema23, nema14

# softward Control :

# 'fullstep': A cycle = 200 steps

# 'halfstep': A cycle = 200 * 2 steps

# '1/4step': A cycle = 200 * 4 steps

# '1/8step': A cycle = 200 * 8 steps

# '1/16step': A cycle = 200 * 16 steps

# '1/32step': A cycle = 200 * 32 steps

"""

#

# mirror e-paper Start Program page instructions to command line console.

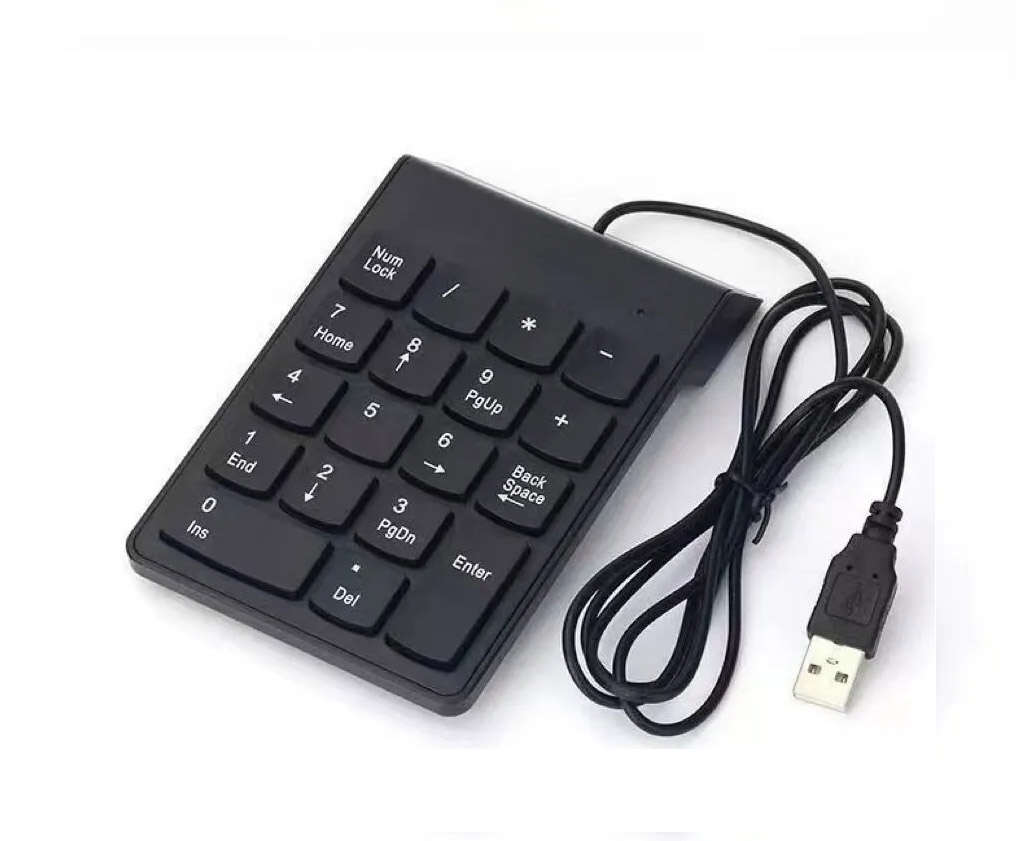

print("To start process:")

print("Enable numlock on keypad if present")

print("Enter 1 to enable buzzer")

print("Enter 0 to disable buzzer")

while True:

try:

z = input("Enter 1 or 0: ")

z = int(z)

if z == 0:

break

elif z == 1:

break

except:

print("Invalid input") # prints error to console if input is not numeric

# and then loops back so user can try again - if you're only using the e-paper

# display there is no error message but you can nevertheless try again

print("")

print("Press button 'B' on the controller")

buttonB.wait_for_press()

#

# get the number of gear teeth to be cut while also checking that the input is numeric

# check is because numeric USB keypads output non-numeric ASCII codes when numlock is inactive

# checking with "while True" loop allows user to keep trying until they get it right

# (fopr example if they forgot to enable numlock)

#

while True:

try:

t = input("Enter the number of gear teeth: ")

if t.isnumeric():

break

except:

print("Invalid input") # prints error to console if input is not numeric

# and then loops back so user can try again - if you're only using the e-paper

# display there is no error message but you can nevertheless try again

#

t = int(t) # make t an integer type variable as gear teeth can only be integers

a = 360.0/t # calculate the angle "a" per tooth by dividing 360 by the number of teeth

# save a rounded to 3 decimal places version of the variable "a" for use on the display

# so we're not displaying unnecessary / irrelevant decimal places

angle = round(a,3)

time.sleep(0.5) # pause for a half second

print("")

print(t,"gear teeth calculated")

print("")

print("Wait for backlash reset")

print("")

# 100 steps is approximately 5 degrees at the current 1/32 step microstepping ratio

print("Rotating 100 steps (~five degrees) to zero out any backlash in the gear train")

print("")

time.sleep(0.5)

# the next line uses gpiozero TonalBuzzer to play a tone on a hardware buzzer inside the controller

# this tone plays whenever the motor is moving as a reminder not to move the cutter while the motor

# is active

if z == 1:

b.play(Tone(220.0)) # start playing a 220 Hz buzz audio prompt through gpiozero tonal buzzer hardware

brakerelease.on()

Motor2.SetMicroStep('softward','1/32step') # set the motor mode to fullstep under software control

#

# reverse & then advance ~5 degrees to take up any backlash (slack) in the gear train.

#

# note that because the forward and reverse numbers cancel each other out this process

# can be repeated without skewing relative teeth positions for multiple cutting passes

# or to resume cutting after a temporary interruption (i.e. forgetting to cut a slot, or

# realizing that the slots all need to be deeper, or changing cutters, etc.)

#

# also note that if direct drive microstepping is used without a gearbox

# there should not be any backlash in the direct driving of the drawbar

# however, because of the snapping into position when any stepper motor is first powered on

# it's good to leave this bit in - it also allows you to check that the motor is controlling the spindle

# and that the spindle is moving freely before cutting the first slot

#

Motor2.TurnStep(Dir='backward', steps=100, stepdelay = 0.003)

time.sleep(0.5)

if z == 1:

b.stop() # turn off the 220 Hz buzzer to indicate that the motor has stopped moving

time.sleep(0.25)

if z == 1:

b.play(Tone(220.0)) # start playing a 220 Hz buzz audio prompt through gpiozero tonal buzzer hardware

Motor2.TurnStep(Dir='forward', steps=100, stepdelay = 0.003)

time.sleep(0.5)

if z == 1:

b.stop() # turn off the 220 Hz buzzer to indicate that the motor has stopped moving

brakerelease.off()

#

# set cummulative step register (totalsteps) to 0 before starting loop

# this is necessary to calculate the absolute position of the motor to compensate for

# rounding errors because the number of integer steps per gear slot cut can vary plus or

# minus one step as a result of rounding

# this variation is only 1/6400 of a 360 (0.0562 degrees), which is equal to 3.372 arc minutes

# one arc minute is 1/60th of a degree (0.016666...), or 1/21,600 of a full 360 circle

# 3.372 arc minutes is probably less error than the positional tollerance

# of the milling attachment spindle, however, for greater accuracy a gearbox with a further reduction ratio

# can be added to the system

totalsteps = 0 # total steps "register" (variable) starts at zero

n = 1 # intiate variable "n" ("n" for number of teeth slots cut)

#

# now that n has a value we can update page 3 to include that value as a variable that changes

# with each gear tooth slot cut

#

page3 = f"""C) RUN PROGRAM

{t} gear teeth calculated

{angle} degrees per tooth

You may now cut gear

slot {n} When finished

enter {n} (or 999 to

return to zero position) """

# next we have what I will call the minor while True loop that starts the gear slot cutting and then

# drops us into what I will call the major while true loop

#

# do the following while loop for the number of gear teeth (t) specified

# NOTE: we're calculating the next position in advance so that it can be displayed and the user can

# confirm that the data for the next position is correct before cutting the first position

# because of this the formulas that display the current position require subtracting the steps to the

# next position

#

while n <= t:

# the alert.play() line below and pygame import at beginning of the script play the audio prompt to

# the system sound device (HDMI out, USB speaker, headphone, etc) to indicate the next slot can be cut

# this is different than the buzzer audio which is to indicate that the motor is moving

#

alert.play() # play a brief system audio beep to signal that the gear slot can now be cut

#

# in the following print statement n is always 1 because after we pass this part of the script

# we drop into the major loop for the remainder of the slots

# the reason for this is so that we can drop out of the main loop before the last slot and advance

# back to the start position

#

print("You may now cut gear tooth slot",n)

print("")

try:

printToDisplay(page3)

except:

print("display error")

print("")

#

# calculate the total angle 'a' of the current position and subtract the n = 1 angle so the

# first cut starts at zero angle

a = 360.0/t*n-360.0/t

# print the current angle in degrees rounded to three decimal places to console

print("Angle: ",str(round(a,3)),"degrees")

# calculate current position in steps by multiplying steps-per-slot

# (6400/t) by current number of slots 'n'

absolute_position = (6400.0/t)*n

# print the current position as the current absolute position minus one gear tooth so the

# first cut starts at zero steps

print("Current position:",str(int(round(absolute_position-6400.0/t))),"steps of 6400 steps total")

# subtract totalsteps from absolute position to get newsteps

# this is where we use the non-zero absolute position to calculate how many new steps to advance

newsteps = int(round(absolute_position - totalsteps))

#

print("")

#

# now we drop into the major while True loop

#

while n < t: # until the last cut (n = t) repeat the following loop:

totalsteps = totalsteps + newsteps # accumulate the total steps with each pass through this loop

print("(next rotation will be",newsteps,"steps to angle",str(round(360.0/t*n,3)),"degrees)")

print(" ")

# do the following loop for the number of gear teeth (t) specified

# NOTE: this loop is for all slots subsequent to the first slot

while True:

try:

confirm = input("Enter completed slot number to continue (or '999' to return to zero): ")

print("")

if int(confirm) == int(n):

break

elif int(confirm) == 999:

n = t - 1

print("")

print("Motor will return to zero after the next cut position")

print("")

break

except:

print("Invalid input")

page3A = f"""C) RUN PROGRAM

Please wait while the motor

advances """

try:

printToDisplay(page3A)

except:

print("display error")

# the next line uses gpiozero TonalBuzzer to play an audio prompt on a hardware buzzer inside

# the controller

if z == 1:

b.play(Tone(220.0)) # play audio prompt through gpiozero tonal buzzer hardware

brakerelease.on()

print("Rotating to next cut position")

Motor2 = HR8825(dir_pin=24, step_pin=18, enable_pin=4, mode_pins=(21, 22, 27))

Motor2.TurnStep(Dir='forward', steps=newsteps, stepdelay = 0.003)

time.sleep(0.1)

last = str(n)

n = n + 1

page3 = f"""C) RUN PROGRAM

Slot {last} of {t} completed

You may now cut gear

slot {n}

When finished enter {n}

(or 999 to return to

zero position) """

time.sleep(0.1)

if z == 1:

b.stop()

brakerelease.off()

print(" ")

print("You may now cut gear tooth slot",n)

# the alert.play() line below and pygame import at beginning of script play audio prompts

# through system sound device (HDMI out, USB speaker, headphone, etc)

alert.play()

try:

printToDisplay(page3)

except:

print("display error")

a = 360.0/t*n-360.0/t

print("Angle: ",str(round(a,3)),"degrees")

absolute_position = (6400.0/t)*n

print("Current position:",str(int(round(absolute_position-6400.0/t))),"steps of 6400 steps total")

newsteps = int(absolute_position - totalsteps)

print("This is the final cut position")

print("The next calculated position is the zero position:",str(int(absolute_position)),"steps total")

print("")

while True:

try:

confirm = input("Enter completed slot number to continue: ")

if int(confirm) == int(n):

break

except:

print("Invalid input")

page3A = f"""C) RUN PROGRAM

Please wait while the motor

advances """

try:

printToDisplay(page3A)

except:

print("display error")

print(" ")

print("Rotating to initial cut position")

if z == 1:

b.play(Tone(220.0)) # play audio prompt through gpiozero tonal buzzer hardware

brakerelease.on()

Motor2 = HR8825(dir_pin=24, step_pin=18, enable_pin=4, mode_pins=(21, 22, 27))

Motor2.TurnStep(Dir='forward', steps=newsteps, stepdelay = 0.003)

if z == 1:

b.stop()

alert.play()

n = n + 1

print("Completed index cycle for ",t,"gear teeth")

time.sleep(0.5)

a = 360.0/t

page3 = f"""C) PROGRAM ENDED

{t} gear teeth cut

{angle} degrees per tooth

Press button 'D' on this unit

to continue

"""

try:

printToDisplay(page3)

except:

print("display error")

time.sleep(1)

print("")

print("Press button 'D' on the controller to continue")

print("")

buttonD.wait_for_press()

try:

endloop = input("Enter 0 to shut down, 1 to start over, or 2 to end the program: ")

print("")

if int(endloop) == 0: # end program and power off

print("Clear e-paper display") # print to console to indicate that e-paper display is being cleared

epd.Clear() # clear the e-paper display

time.sleep(2)

print("\nMotor stop")

Motor2.Stop()

os.system('sudo poweroff')

exit()

break

elif int(endloop) == 1: # start over at the top of process

print("Clear e-paper display") # print to console to indicate that e-paper display is being cleared

print("")

epd.Clear() # clear the e-paper display

time.sleep(2)

elif int(endloop) == 2: # terminate the program

exit()

except:

exit()

except:

print("Clear e-paper display") # print to console to indicate that e-paper display is being cleared

epd.Clear() # clear the e-paper display

epd2in7_V2.epdconfig.module_exit

print("\nMotor stop")

Motor2.Stop()

exit()

|